Sometimes fiber termination in the field needs to be finished quickly and effectively. Then how to achieve the perfect termination result we want? Today this article will introduce a new type of connector—field installable connector which enables users to get the ideal solution for their field installations. Hope it can help you.

Generally, the connectors we know comprise fiber ferrule, connector sub-assembly body, connector housing and fiber cable. Except for those, field installable connector is a little different. It is a kind of connector that is pre-polished in factory, which aims to offer users a fast, easy and reliable termination way. And if field installation connectors deployed in cable installation, the termination time will be less than two minutes without any difficulty and require no epoxy, polishing or crimping. That’s why field installable connectors are so popular.

As we all know, the most critical point in any optical interconnect is the physical contact interface between mated connector pairs. When fiber optic connectors are polished, a small lens, of which shape impacts the light transmission, is produced at the tip of the connector. Therefore, compared with common connectors, pre-polished field termination connectors provide more reliable, lower insertion loss and less return loss connection performance.

Field installable connectors have different types according to different standards. For example, according to the connector types, there are LC, SC and FC connectors. While according to the connection type of the fiber and the stub, field installable connector can be divided into mechanical field installable connector and fusion splice-on field installable connector. Here is a brief introduction to them.

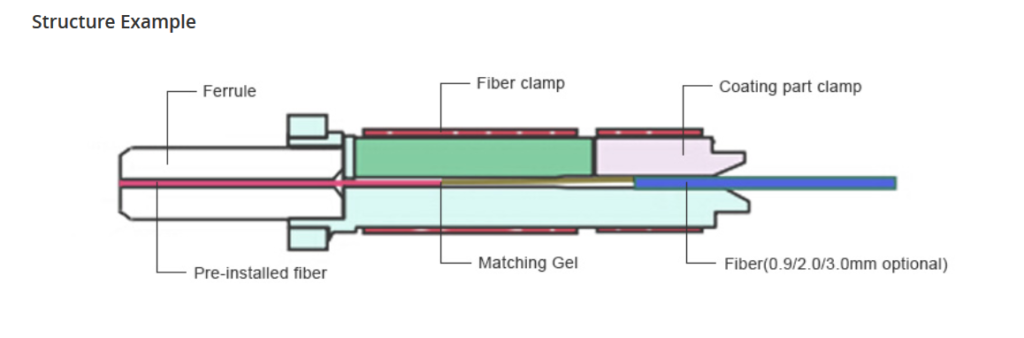

The mechanical connector is a product that evolved primarily out of the enterprise space, and offers a simpler and cleaner alternative to the epoxy-and-polish connectors which preceded it. As its name implies, mechanical field installable connector uses a mechanical method to align a cleaved fiber with the pre-polished stub and then use a cam, wedge, or crimp mechanism to secure the fibers together. In essence, it is a connector end-face and a mechanical splice in one package and within a few millimeters distance of one another. And this kind of field installable connector can be used for both indoor and outdoor applications.

A fusion splice-on field installable connector utilizes a fusion splicer to joint a fiber stub inside the connector with a fiber cable permanently. The splicing is protected within the boot of the connector, replacing the need for traditional pigtails because the splice is contained within the connector. The connector can be directly terminated using the patch panel’s existing cable management features. Compared to mechanical field installable connector, fusion splice-on connector has more advantages such as more flexibility, higher reliability, lower insertion loss and higher return loss.

In the last paragraph, we have mentioned that field installable connector can help users install cables in a quick way. However, it has other advantages. Here are the comprehensive benefits that field installable connectors can provide.

As we have mentioned above, field installable connectors can simplify the termination process, which greatly reduces the installation time and set-up time. Unlike the common connectors, field installable connectors require no other tools to do the fiber termination. Only with the basic fiber preparation tools, a satisfactory installation can be achieved. It’s because of these simple procedures that training becomes easy. Therefore, there is no need of more labors.

Field installable connectors also reduce out-of-pocket cost. On one hand, no other tools needed means less money needs to be spent. On the other hand, since the installation way becomes simpler, the extra material cost that may be caused by installers due to misoperation can be eliminated.

Field installation connectors are designed to enable fast and easy fiber termination. Its factory pre-terminated ferrule can help operators reduce installation errors effectively. And they also can save time and cost for users. FS.COM offers several kinds of field installation connectors with cheap price. Hope you can select the most suitable one for your project.