When it comes to optical fiber communication, we are impressed with its fast speed, large information capacity and bandwidth. To achieve this result, numbers of optical components play key roles in optical systems. Optical amplifier is one of them. When transmitted over long distance, the optical signal will be highly attenuated. On this situation, optical amplifier makes a difference. Today, this article will give a brief overview about optical amplifier to help you learn more about it.

What Is an Optical Amplifier?

Usually a basic optical communication link consists of a transmitter and receiver, with an optical fiber cable connecting them. Even if signals in fibers suffer less attenuation than in other mediums, there is still a limited distance about 100 km. Beyond this distance, the signal will become too noisy to be detected.

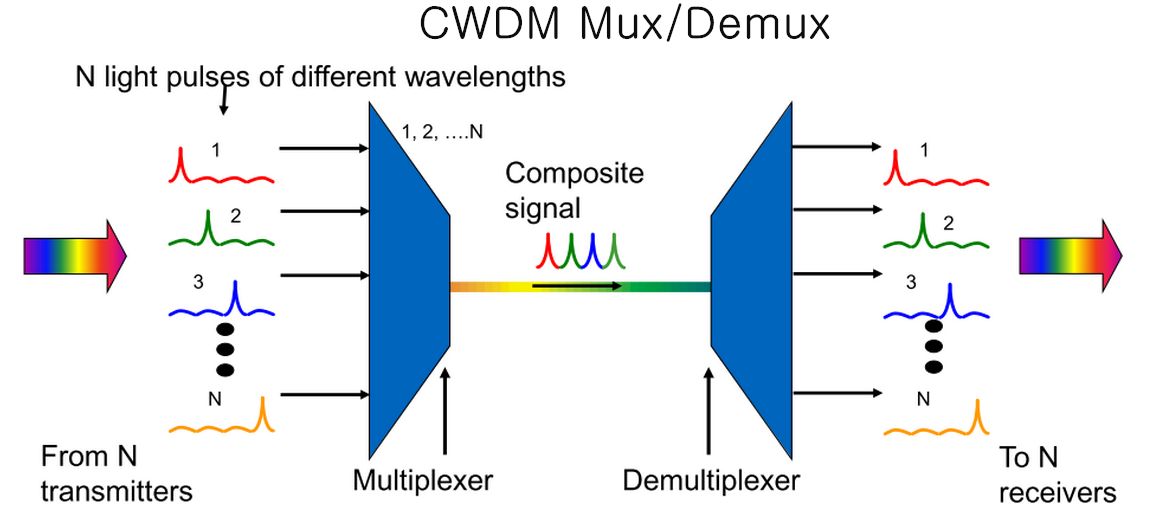

Optical amplifier is a device designed to directly amplify an input optical signal, without needing to transform it first to an electronic signal. And at the same time, it can strengthen the signal, which is conducive to transmission over long distances. Here is a comparison figure. In the (a), it is an electrical signal regeneration station. We can see all the channels are separated, signals detected, amplified and cleaned electrically, then transmitted and combined again. However, in the figure (b), it is an optical amplifier in which all channels are optically and transparently amplified together. Compared to electrical amplifier, optical amplifier is more cost-effective. Because it amplifies signals directly, and needs less cost.

Common Types

Generally, there are three common types optical amplifier: the erbium doped fiber amplifier (EDFA), the semiconductor optical amplifier, and the fiber Raman amplifier.

The amplifying medium of EDFA is a glass optical fiber doped with erbium ions. The wavelength near 1550 nm can be amplified effectively in erbium doped optical fiber amplifiers. What’s more, EDFA has low noise and can amplify many wavelengths simultaneously, making EDFA widely used in optical communications. According to the functions, EDFA usually has three types: booster amplifier, in-line amplifier and pre-amplifier.

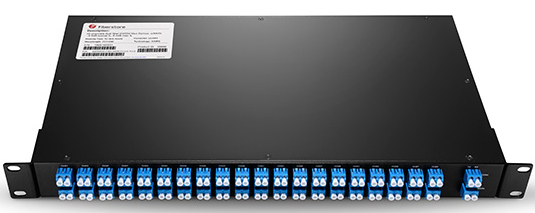

A booster amplifier operates at the transmission side of the link, designed to amplify the signal channels exiting the transmitter to the level required for launching into the fiber link. It’s not always required in single channel links, but is an essential part in WDM link where the multiplexer attenuates the signal channels. It has high input power, high output power and medium optical gain. The common types are 20dBm Output C-band 40 Channels 26dB Gain Booster EDFA, 16dBm Output C-band 40 Channels 14dB Gain Booster EDFA and so on. Of course, there are still different specification of booster amplifiers which cannot be listed here. Here is a picture of 23dB Output 1550nm Booster EDFA Optical Amplifier.

An in-line amplifier typically operates in the middle of an optical link, which is designed for optical amplification between two network nodes on the main optical link. It features medium to low input power, high output power, high optical gain, and a low noise figure.

At the end a pre-amplifer makes a difference. Pre-amplifier is used to compensate for losses in a demultiplexer near the optical receiver. It has relatively low input power, medium output power and medium gain.

Semiconductor optical amplifier (SOA) uses a semiconductor to provide the gain medium. It operates with less power and is cheaper. But its performance is not as good as EDFA. SOA is noisier than EDFA. Therefore, SOA is usually applied in local area networks where performance is not required but the cost is an important factor.

In a fiber Raman amplifier, power is transferred to the optical signal by a nonlinear optical process known as the Raman effect. Distributed and lumped amplifiers are the two common types of Raman amplifier. The transmission fiber in distributed Raman amplifier is utilized as the gain medium by multiplexing a pump wavelength with the signal wavelength, while a lumped Raman amplifier utilizes a dedicated, shorter length of fiber to provide amplification. Here is a Raman amplifier.

Conclusion

Optical amplifiers perform a critical function in modern optical networks, enabling the information transmitted over thousands of kilometers and providing the data capacity which current and future communication networks are required. Amplifiers mentioned above are available in Fiberstore. If you are interested, please visit FS.COM for more information.