Nowadays, with the further popularization of the optical fiber communication, fiber optic splitter plays an increasing significant role in many of today’s optical network topologies. Although there are variations of splitter types, the two most commonly deployed splitters are FBT (Fused Biconical Taper) splitter and PLC (Planar Lightwave Circuit) splitter. So, when you deploy your network, what kind of splitter you should choose may be a problem for you. And in order to solve this problem, this paper will give you a detailed introduction of differences between FBT splitter and PLC splitter.

Before you get to know the features of them, first you should know what them are. Next, each splitter will be introduced.

FBT Splitter – FBT is a traditional technology that two fibers are typically twisted and fused together while the assembly is being elongated and tapered. The fused fibers are protected by a glass substrate and then protected by a stainless steel tube, typically 3mm diameter by 54mm long. FBT splitters are widely accepted and used in passive optical networks, especially for instances where the split configuration is not more than 1×4. The slight drawback of this technology is when larger split configurations such as 1×16, 1×32 and 1×64 are needed.

PLC splitter – A PLC splitter is a micro-optical component based on planar lightwave circuit technology and provides a low cost light distribution solution with small form factor and high reliability. It is manufactured using silica glass waveguide circuits that are aligned with a V-groove fiber array chip that uses ribbon fiber. Once everything is aligned and bonded, it is then packaged inside a miniature housing. PLC Splitter has high quality performance, such as low insertion loss, low PDL (Polarization Dependent Loss), high return loss and excellent uniformity over a wide wavelength range from 1260 nm to 1620 nm and have an operating temperature -40°C to +85°C.

In the past few years, splitter technology has made a huge step forward, especially the PLC splitter technology. This situation resulted in that PLC splitter has become a higher reliable type of device compared to the traditional FBT splitter. Although being similar in size and appearance, the internally technologies behind these types vary, thus giving service providers a possibility to choose a more appropriate solution.

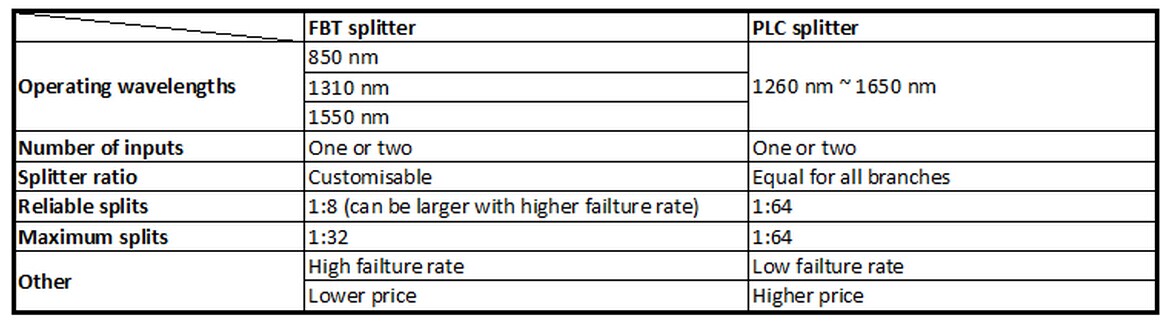

Operating Wavelength – As is mentioned above, PLC splitter can provide a range of operating wavelength from 1260 nm to 1620 nm. But FBT splitters only support three wavelengths (850/1310/1550 nm) which makes these devices unable to operate on other wavelengths.

Operating Temperature – Commonly, FTB splitter is to a high extent temperature sensitive, providing a stable working range of -5 °C to 75 °C. While PLC splitter operates at wider temperature range (-40 °C to 85 °C), allowing its deploying in the areas of extreme climate.

Split Ratio – The split ratio of FBT splitter is 1:8 and it can be higher with higher failure rate. The split ratio of PLC splitter can go up to 64, which is equal to all branches, thus providing a high reliability.

Cost – FBT splitter is made out of materials that are easily available, for example steel, fiber, hot dorm and others. All of these materials are low-price, which determines the low cost of the device itself. PLC splitter manufacturing technology is more complex. It uses semiconductor technology (lithography, etching, developer technology) production, hence it is more difficult to manufacture. Therefore, the price of this device is higher.

In a word, Compared with FBT splitter, the capacity of PLC splitter is better, but costlier than the FBT splitter in the smaller ratios. You can choose it according to your requirements. Fiberstore offers both FBT splitter and PLC splitter with good quality and low price. Whether in FTTx systems or in traditional optic network, Fiberstore splitter can help you to maximize the functionality of optical network circuits.