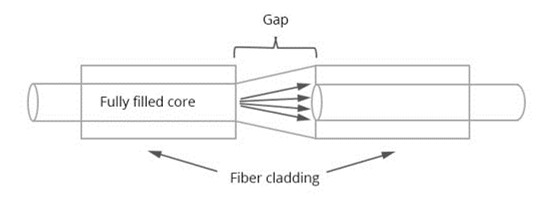

Fiber cable connectors are designed to provide perfect alignment of the microscopic glass fibers that were used in fiber cables to transmit data. These kinds of connections must be highly accurate in order to facilitate high speed fiber optic networks. This article helps to review some common fiber cable connector types available on the market today.

What Is Fiber Cable Connector?

Fiber cable connector, also named fiber optic connector or optical fiber connector, is a hardware installed on fiber cable ends. It provides cable attachment to a transmitter, receiver or other cable. There are various fiber cable connectors, for which different connectors have different characteristics and functions. According to statistics, about 100 different types of fiber cable connectors have been introduced to the market.

Fiber Cable Connector Constructions

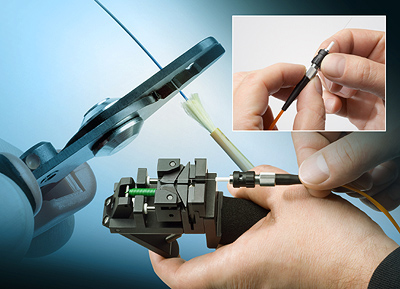

The most popular used ones are ST, SC, FC and LC style connectors, which vary differently from characteristics, applications and performances. But all the connectors have three major components: the ferrule, the connector body, and the coupling mechanism. Among those, the ferrule is used for protecting and aligning the stripped fiber end. The connector body holds the ferrule and attaches to the jacket and strengthens fiber cable. The coupling mechanism is a part of the connector body that keeps the connector in place when connected to other devices.

Common Fiber Cable Connectors and Their Differences

ST connector was developed by AT&T. It’s a high-performance fiber optic connector with cylindrical ceramic ferrules and bayonet locking features. Most ferrules are ceramic, but some are metal or plastic. ST connector is constructed with a metal housing and is nickel-plated, can be inserted into and removed from a fiber optic cable both quickly and easily. It’s commonly used in network environments such as campuses, corporate networks, industrial and military applications.

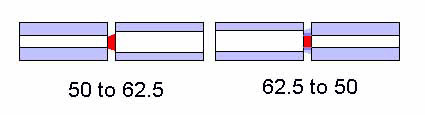

SC connector is a snap-in connector with a round 2.5mm ferrule used to hold a single mode fiber (SMF). It sometimes refers to “square connector” because of its “square shaped” connector body. It’s intended for Gigabit Ethernet networking with features of low price and excellent performance. SC connector is ideal for data communication and telecommunications applications, and still popular over the years.

FC Connector is the first optical fiber connector to use a certain ferrule. It utilizes a round screw-type fitment made from nickel-plated or stainless steel. The end face relies on an alignment key for correct insertion and is then tightened into the adaptor/jack using a threaded collet. It’s commonly used in data communication, telecommunications, measurement equipment, and single-mode lasers. SC and LC connector deliver similar performance to FC connector but both of them have less expensive components, thus FC connector with screw-on collet performs effectively in high-vibration environments.

LC connector is featured with a ferrule of 1.25mm, which makes it perfect for high density cabling. It’s available in simplex and duplex versions. It has half the footprint of the SC connector, thus it becomes the most popular connector in data communication and other high-density patch applications. LC connector is ubiquitous nowadays, especially for connections with SFP and SFP+ fiber transceivers.

Conclusion

There are about 100 fiber cable connectors introducing to the market, but only a few represent the majority of the market. Here is a brief review on fiber cable connectors that have been the leaders of the industry. If you’d like more information on different fiber cable connectors, FS.COM has a complete fiber cable connector guide for you.

Related Articles:

Tips on Buying Fiber Optic Cables

Fiber Optic Cable Core-How Much Do You Know About It?

How Many Fiber Connector Types Do You Know?