Networking patch panel has been an indispensable part in daily cabling. Whenever setting up connections for all sorts of devices, like servers and switches, you have to deal with a large number of input and output cables. Under such a circumstance, the patch panel for networking will do help to effectively manage those cumbersome cables. Then, a series of questions about patch panel in networking ensued. In this post, what a networking patch panel is and why it is needed will be answered.

Figure 1: Network Cabling

What is the Networking Patch Panel

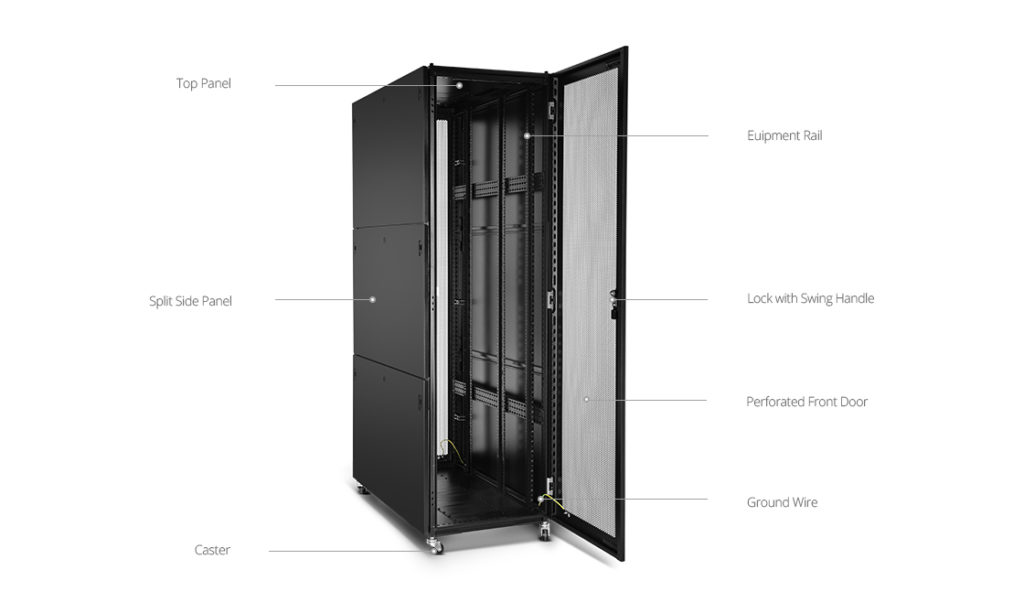

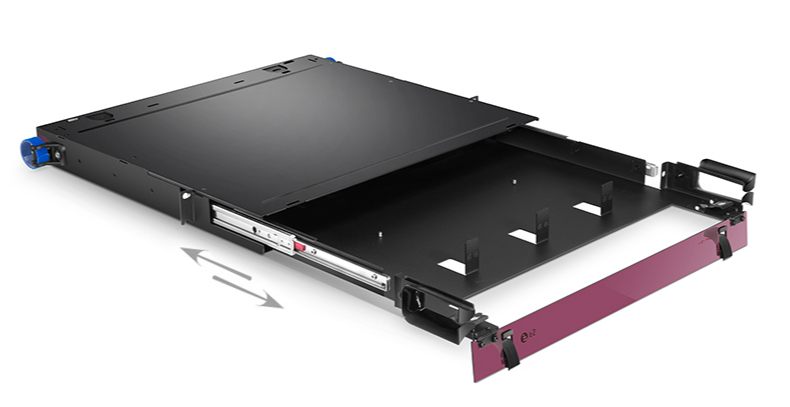

Networking patch panel, a kind of cable organizer, is designed to connect and manage copper or fiber optic cables coming in or out. Usually, in networking patch panel cabling, the panel will be attached to racks or enclosures in wiring closets or on walls. Then, patch cords will be used to connect ports in patch panels to ports in servers or network switches.

Types of Networking Patch Panel

Basically, according to the cables connected, there are two types of networking patch panel: Ethernet patch panel and fiber optic patch panel.

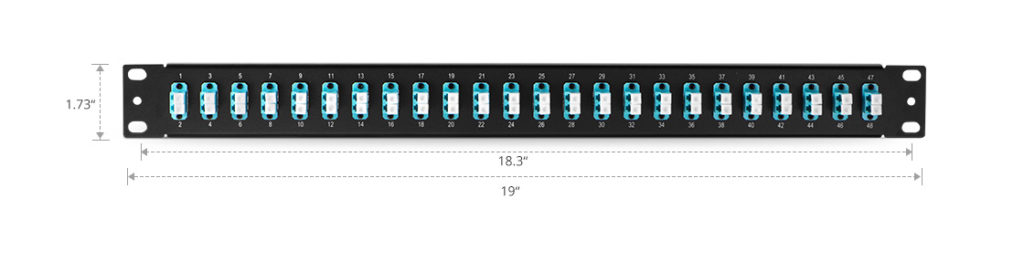

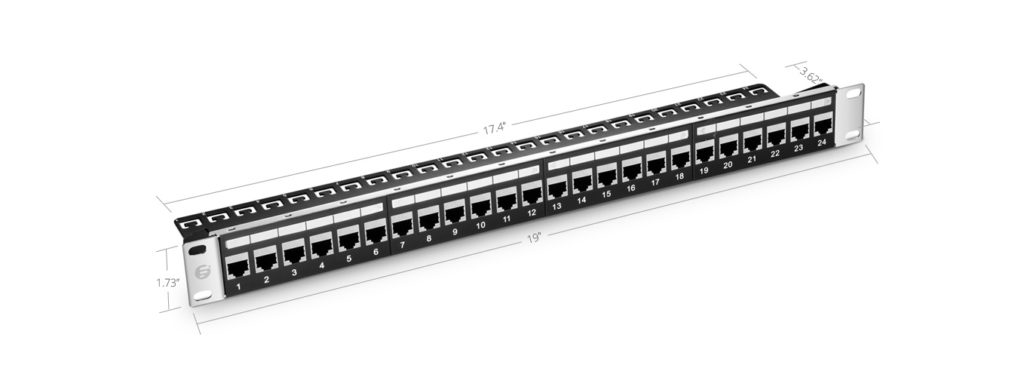

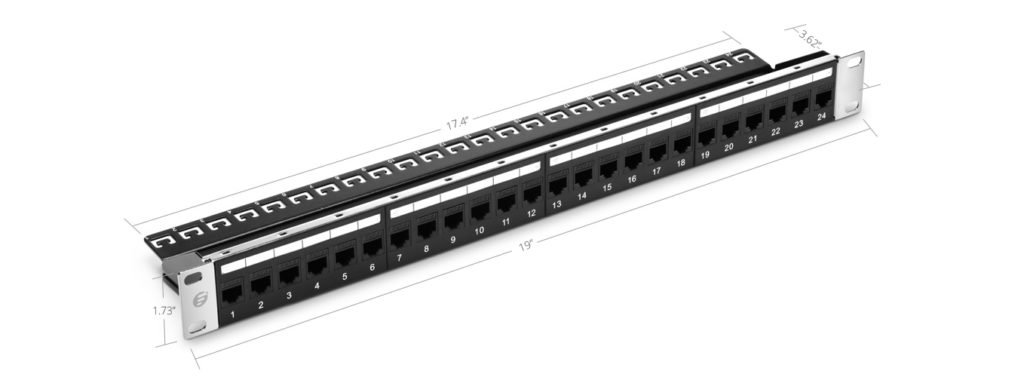

Ethernet patch panel, also called copper patch panel, provides interconnections for Ethernet applications in local area network. There are many types of Ethernet patch panels, among which Cat5e patch cable, Cat6 patch cable, and Cat6a patch cables are commonly used in network cabling. As for ports of the copper patch panel, various options also can be found, such as 24 ports and 48 ports. If you want to buy an Ethernet panel, you still have to consider its designs: shielded or unshielded, flat or angled, punch down or feed-through, and loaded or unloaded. With various options, you can always find a needed type.

Figure 2: 24 Ports Blank Keystone Ethernet Patch Panel (Left) and 24 Ports Cat6 Shielded Feed-Through Patch Panel (Right)

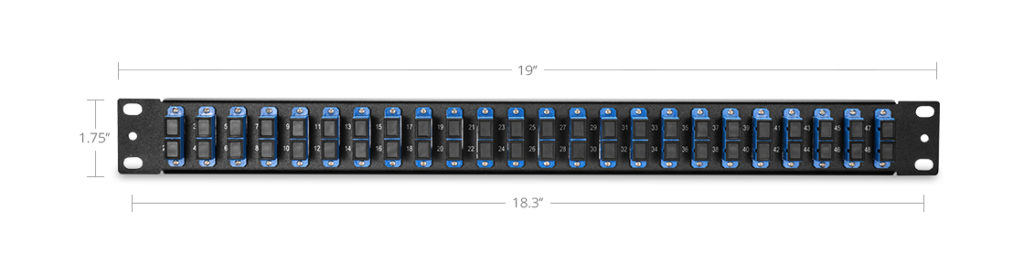

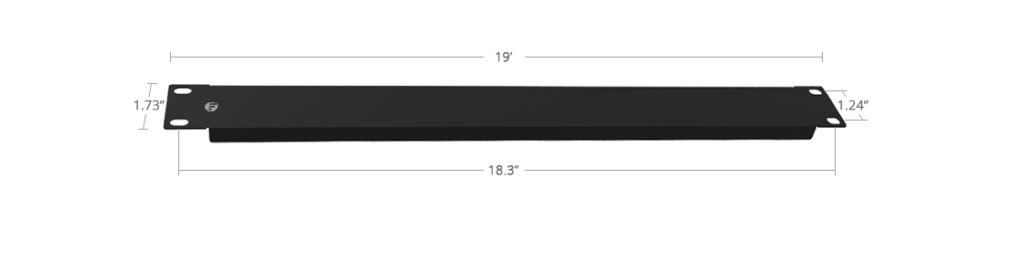

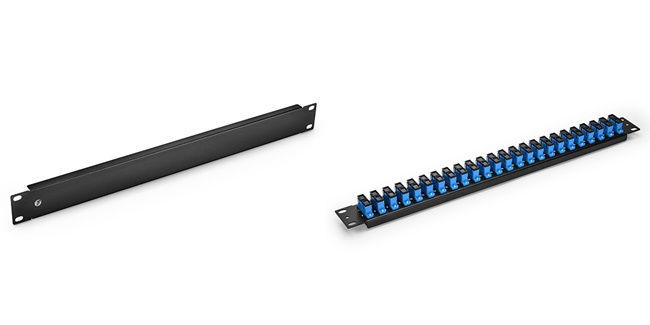

Fiber optic patch panel, the other branch of networking patch panel, is designed to organize fiber cables. Similar with Ethernet patch panels, the fiber optic patch panels also are varied in designs, such as adapter types, fiber types and fiber count. Conventionally, fiber optic patch panel is commonly used as rack mount fiber patch panel or wall mount patch panel, which also applied for the Ethernet patch panel.

Figure 3: Blank Fiber Patch Panel (Left) and FHU 1U 48F SC Patch Panel (Right)

Benefits of Patch Panel in Networking

Knowing what the networking patch panel is just partly solves the concern, what is the purpose of patch panel in networking? Understanding the benefits of network patch panel, the question can be solved. Commonly, there are four major benefits shared by networking patch panels:

First, saving time. With a patch panel in networking, changes and repairs of cables are much easier for IT technicians. They don’t need extract time to clear and identify cables.

Second, space saving. Without messy cabling, you can organize cables in a neat and orderly way. Especially, for high-density cabling, a networking patch panel can help you save a lot of space.

Third, reducing the signal interference. When cables separated in an organized way, it will greatly lower the chance for crosstalk and interference between them. As a result, the networking performance will also be enhanced greatly.

Fourth, cost reducing. With previous benefits, it will definitely bring about cost reduction. You don’t need to spend extra money on repairing, managing and future network expansion.

Summary

After revealing what the patch panel is and why it is used, it’s easy to find the networking patch panel is the best solution to manage cables, no matter in the office or home network. As we mentioned, there are various benefits of networking patch panels. However, if you want to make a full advantage of those benefits, a wise use of patch panels is needed. For detailed information about how to wisely use patch panel manage cables, you can refer to the article: Best Patch Panel Cable Management Techniques.