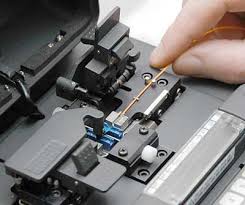

Fiber optical splicing is the act to joint two fibers together by using heat. Generally, there are two types of optical splicing: mechanical splicing and fusion splicing. Fusion splicing cannot be completed without a piece of equipment called fusion splicer. However, you can’t just use it without any maintenance. Do you know how to maintain it in your daily work? Today, this article is to give you some advice for your fusion splicer maintenance.

Fiber optic fusion splicer uses an electric arc to melt two optical fibers at the level of their faces to end and form a long fiber. It connects two fibers permanently so that the optical signals can be transmitted in the fiber with a very low loss.

Before we know how to maintain our fusion splicers, we need to make sense how it works. Only when you know clearly its work process can you get how to avoid some unnecessary mistakes which may cause great damage to your fusion splicer.

Usually, before starting a fusion splicing, the preparations need to be finished: removing all the protective coating, completely clean and then precisely cleaving to form a smooth and perpendicular end faces. When all of these have been done, the fiber optic fusion splicer takes over the rest of the process which includes three steps.

Alignment. With the help of a small but precise motor, the fusion splicer makes tiny adjustments to the fibers’ positions until they are aligned properly. During this process, the fiber optic workers can view the fiber alignment by optical power meter video camera or viewing scope.

Impurity Burn-Off. Since the slightest trace of dust or other impurities can affect the transmission of optical signals, cleaning is always the first important thing needed to be done. Before fusing, fusion splicer can generate a small spark between the fiber ends to burn off the remaining dust or moisture.

Fusion. After fibers have been aligned and thoroughly cleaned, it’s time to fuse the fiber ends together. The splicer emits a second, large spark that melts the optical fiber end faces Then the melted fibers are jointed together.

Now we have know how the fusion splicer works, it’s time to learn something on how to maintain fusion splicer to make sure the fusion procedures go on wheels. Here are some tips on how you can maintain your fusion splicers. These tips are mainly about the cleaning in the fusion process.

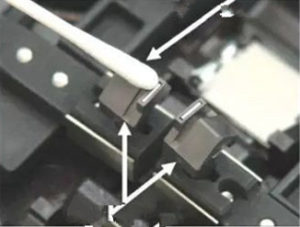

- Clean the V-groove. If there are contaminants in the V -groove, it cannot clamp fiber properly and will cause unnecessary optical loss. Therefore, the V -groove should be checked and cleaned regularly. Generally, a thin cotton swab dipped with alcohol can be used to clean V-groove. If it doesn’t work, first you can use a fiber that has been cleaved to remove the contaminants, and then clean the V -groove with thin cotton swab.

- Clean the Fiber Clamp. If there are dusts on the fiber clamp, it may lead to poor fiber connections. So the cleaning of fiber clamp cannot be ignored in your daily work. Firstly, cleaning the surface of fiber clamp with a thin cotton swab dipped with alcohol. Then dry the clamp with a dry cotton swab.

- Clean the cleaver. Always keep in mind that the cleaver blade should be kept clean, or it will bring dust to the fiber end face, resulting big splice loss. The method to clean the cleaver blade is to clean it with cotton swab.

In order to ensure the quality of fusion splicing, it’s recommended to do regular inspection and cleaning for the fusion splicer. The check items include objective lens, windshield and electrodes.

In summary, it’s vital to maintain fusion splicer to ensure a precise fusion splicing. Of course, good maintenance is necessary, but obviously a good fusion splicer is more important. Fiberstore provides various types of fiber optic splicer and some other accessories which can make splicing much easier and more stable. If you want to know more, please visit FS.com.