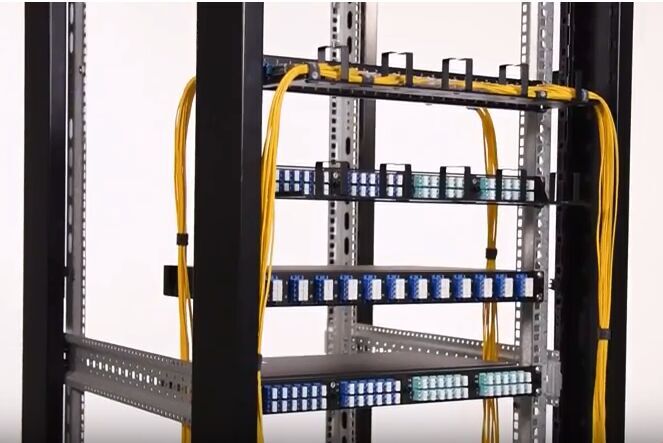

The world changes continuously, and data network has advanced much faster than anyone can keep up. Technicians are tired of dealing with the messy network, and may feel extreme anxiety about the inability to make an organized and structured cabling environment. Fiber optic enclosures are the glue that can connect cables together for delivering data or voice to multimedia and network services like LAN, WAN and ADSL. FS.COM 1U rack mount fiber patch panel cabling solution is the ideal method for easy cable management, including 1U patch panel, FHU 1U 24 port patch panel, and 1U lacer panel and lacing bar.

Function of Rack Mount Fiber Patch Panel

Rack mount fiber patch panel, as a cabling solution, can manage cables easily and connect the cabling distribution areas. This helps pave a way for a neat optical network approach. Often times, it’s used for connecting and disconnecting equipment. Therefore, a rack mount fiber patch panel is the key component for uptime, speed, performance and so on. In addition, with lots of ports in close proximity of the patch panel, cables here can be routed, labeled and monitored, offering a convenient routing option for IT staff.

Cabling Solution Works With Fiber Patch Panels

It’s no doubt that each successful project needs adequate preparation. So once you decide to set up a structured cabling system, it’s time to get right cabling component. Now, here are cabling solution tools offered by FS.COM for your reference.

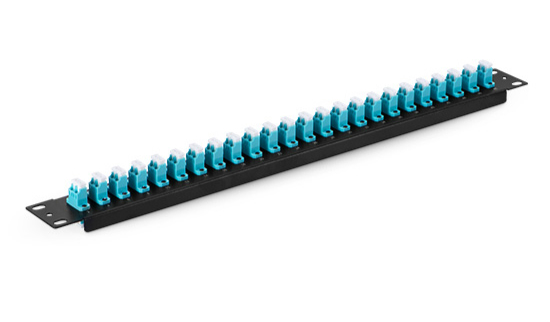

1U rack mount fiber enclosure is designed with 1.55 SPCC steel rack and can hold up to 4 fiber adapter panels (FAPs) and MTP cassettes, allowing for 96 fiber cables installation with simple plug-n-play design.

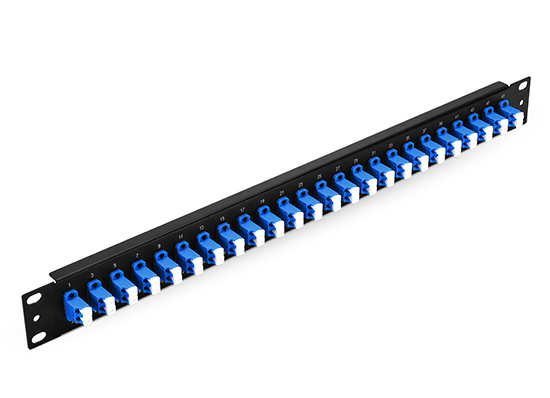

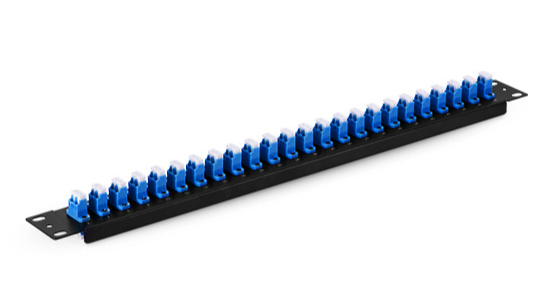

FHU 1U 24 port patch panel serves as standard 1U 19 inches rack with high quality steel adapter. It’s ultra high density but with the correct spacing between the insert parts, for easy deployment. It can connect 96 fiber cables.

1U lacer panel and lacing bar provide multiple choices for your application by being separated into patch panel, d-rings, lacer panel and lacer bar. Together with FHD adapter panels and patch cords, it can make the end-to-end solution.

Installation Steps of 1U Rack Mount Fiber Patch Panel Cabling Solution

After preparing the tools, we should start to install. Cable installation can be a finicky thing. Therefore, to avoid potential network errors and reduce costly mistakes, here are steps for your reference.

- Install 1U rack mount fiber enclosure. Place the mounting brackets at the desired position on the rack. Insert pre-terminated fiber optic cassettes into the enclosure as shown. Once mounted, fully seat fasteners to secure the cassettes.

- Install FHU 1U 24 port patch panel. According to the video, first remove the front panel of the rack mount fiber enclosure, then mount FHU 1U adapter panel onto it. Tighten the screws to make sure it has been installed safely. At last, mount the tool on the rack.

- Install 1U lacer panel and lacing bar. Use screws to fix the tools on the rack, placing the 1U metal lacer panel in front and put the lacer bar at the back. Then place the adapters on the lacer panel.

Finally, plug the fiber cables you need, and use zip ties to fasten the cables. A structured cabling system is completed. If installed properly, one system will last at 10 years and support 2 or 3 generations of fiber equipment.

Conclusion

1U rack mount fiber patch panel cabling solution is easy to install, which can actually manage the cables in an organized way. FS.COM offers a variety of patch panels with good quality to help your network achieve optimum performance. We are always focusing on providing products with superior performance and better services for our customers.